High-cleanness, zero-damage, high-throughput cleaning solutions for

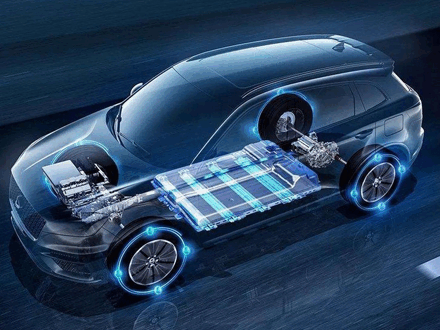

xEV lithium-ion battery structural parts, battery enclosures, and die-cast housings for BMS / e-drive systems

1. Typical cleaning targets & contamination profiles

| Part | Common material | Dominant contaminants | Down-stream requirement |

|---|---|---|---|

| Cell can / top cover | Al 3003 / 6061 | Drawing oil, carbon black, Al fines, oxide film | Laser weld leak-tight ≥ IP67 |

| Battery tray / lower housing | Al-Si die-cast | Mold-release, weld oxide, dust | Adhesive / powder-coat adhesion ≥ Grade 1 |

| Busbar / terminal | Cu-ETP | Oxide, ceramic dust, fingerprints | Laser weld void ratio ≤ 2 % |

| BMS & e-drive housings | ADC12 die-cast | Coolant residues, silicates, grease | Conformal-coat adhesion & Hi-Pot test |

2. Process–equipment–parameter quick selector

| Process step | Recommended technology | Key equipment | Operating window | Key benefits |

|---|---|---|---|---|

| Cell can degreasing & oxide removal | Vacuum hydrocarbon + ultrasonic | Vacuum hydrocarbon machine with ultrasonics & vacuum drying | 55–65 °C, 3–5 min, ≤ 100 ppm residual oil | Zero-waste water, 90 % solvent recovery |

| Deburring tapped holes in cast housings | High-pressure water deburring + vacuum drying | 5-axis 50–100 MPa waterjet + vacuum oven | 30–60 s per hole, ≤ 2 L water/min | Removes M4–M12 blind-hole burrs |

3. Turn-key example: pre-laser-weld cleaning cell

Robot loading: Vision-guided robot picks housing.

In-line QC: Confocal thickness sensor + AI defect detection, real-time feedback of oil/oxide film.

Robot unloading: Vacuum gripper feeds to laser welding station.

Tact time ≤ 12 s / part.

4. Quick selection guide

Fully automatic vacuum hydrocarbon line