Key Features of Single-Chamber CNC High-Pressure Washing Machine

Core Characteristics

• Space-saving single-chamber design with fully enclosed, corrosion-resistant stainless-steel housing.

• CNC control (2-axis or more) driven by industrial PC/PLC; accepts DXF/DWG files and offers multilingual touchscreen interface.

• High-pressure water jets (10–50 MPa) combined with 360° rotating nozzles and pulsating flow remove burrs, oil, carbon deposits and other contaminants from complex geometries without thermal impact.

• Positioning accuracy ≤ 0.05 mm; burr removal rate ≥ 99.9 %; cycle time as short as 5 minutes.

• Integrated drying module—air-knife, hot-air or vacuum drying—ensures residue-free bores and cavities.

• Ready for automation: seamless integration with CNC machining centers for “machine-wash-dry” inline operation; remote diagnostics and MES connectivity; quick program changeover for different parts.

• Eco-friendly: uses only water or water-based agents, closed-loop water recycling, low noise (≤ 75 dB).

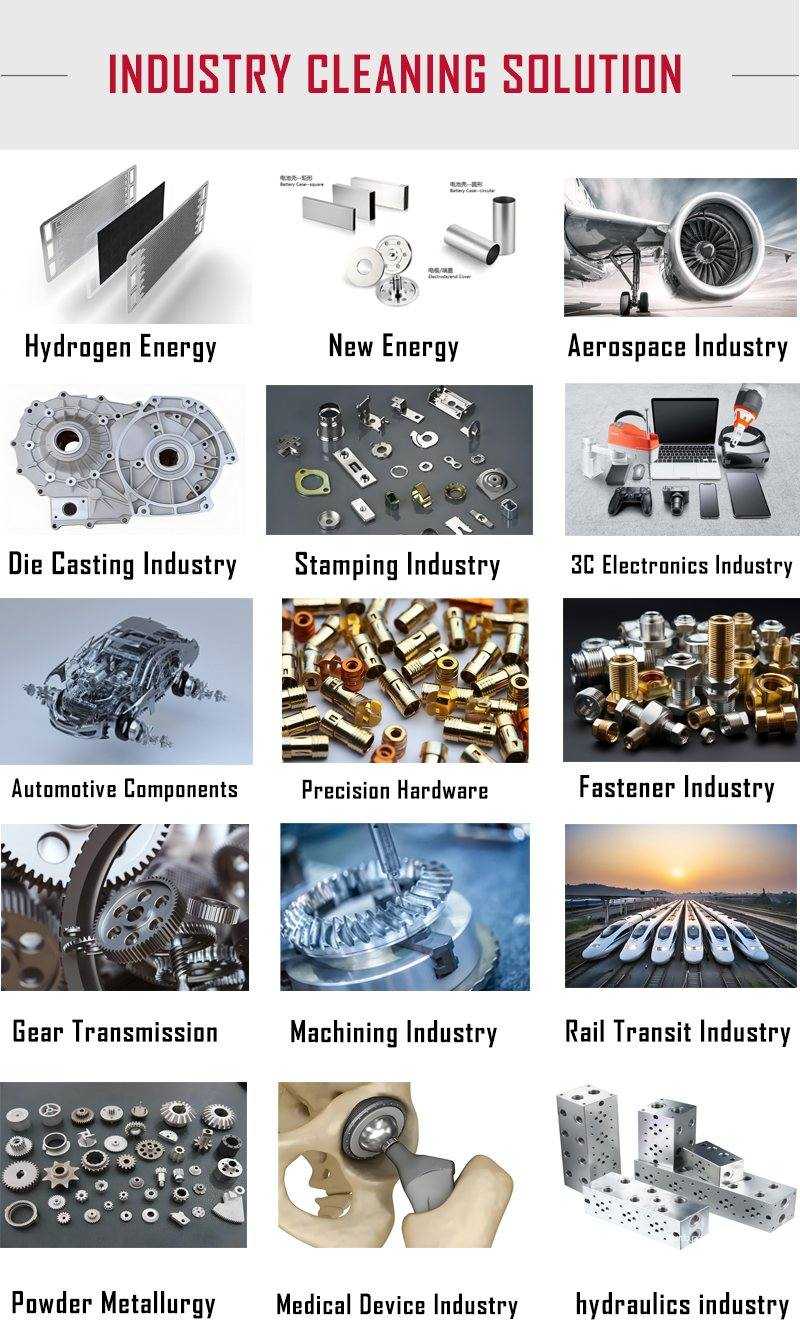

Typical Applications

Automotive castings, aerospace precision parts, medical devices, molds, and battery housings for new-energy vehicles.